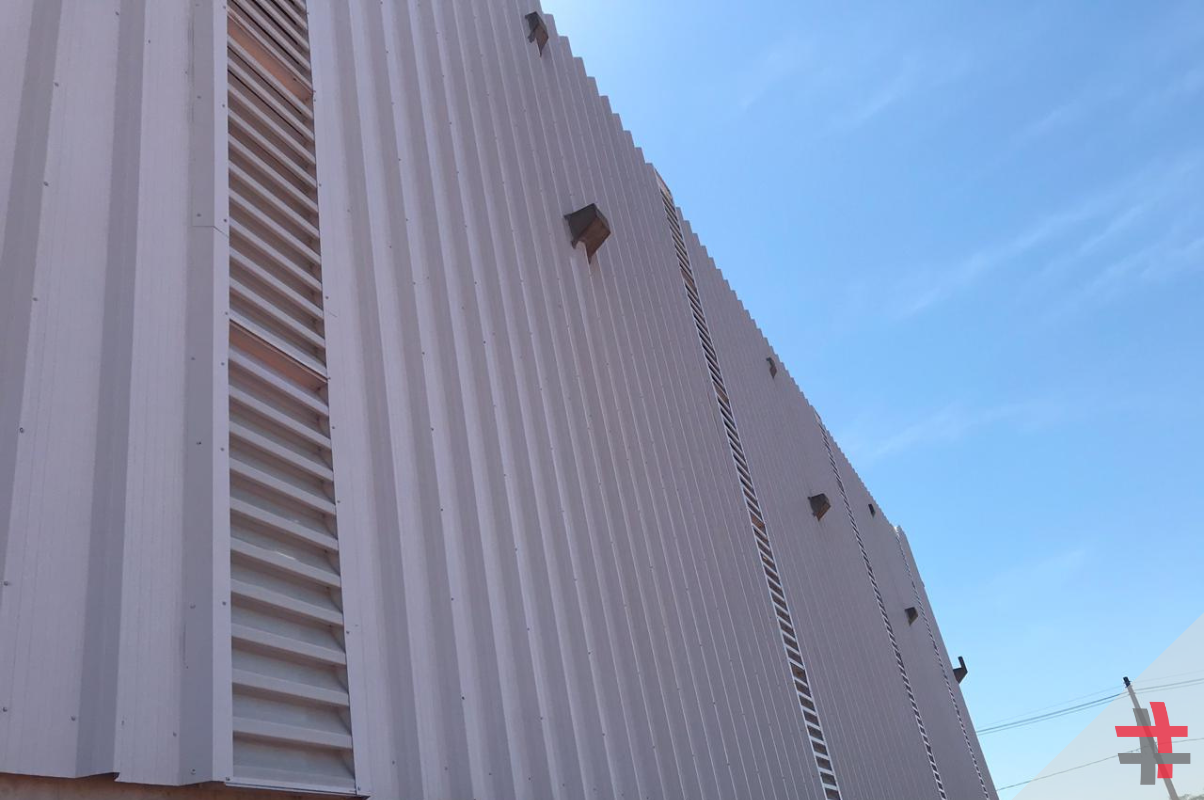

PERFECT FIT FOR DIFFERENT ROOF FORMATS

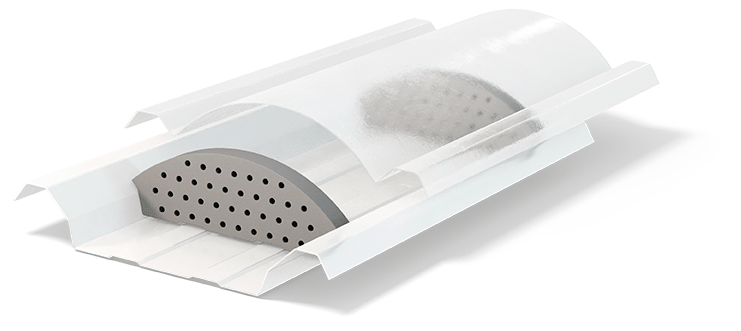

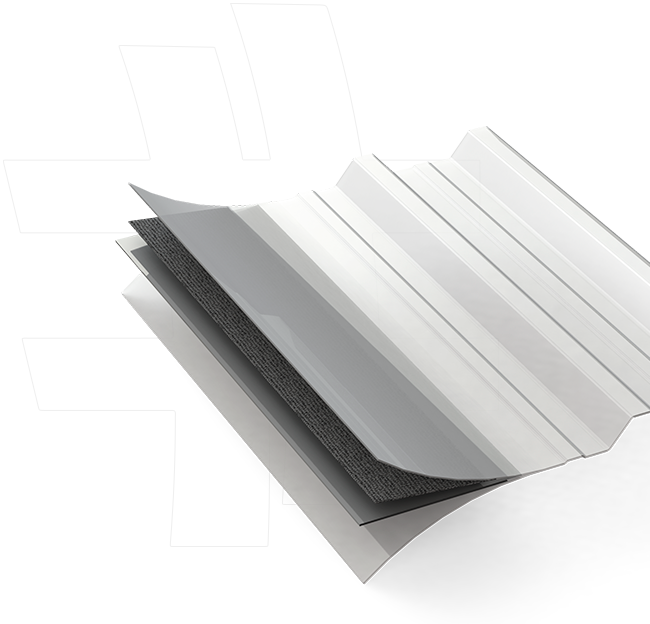

Provide high quality in natural lighting, for different types of buildings. They count with a project that is innovative, the first of its kind, one that, through an air pocket, provides thermal insulation between the external and internal environments